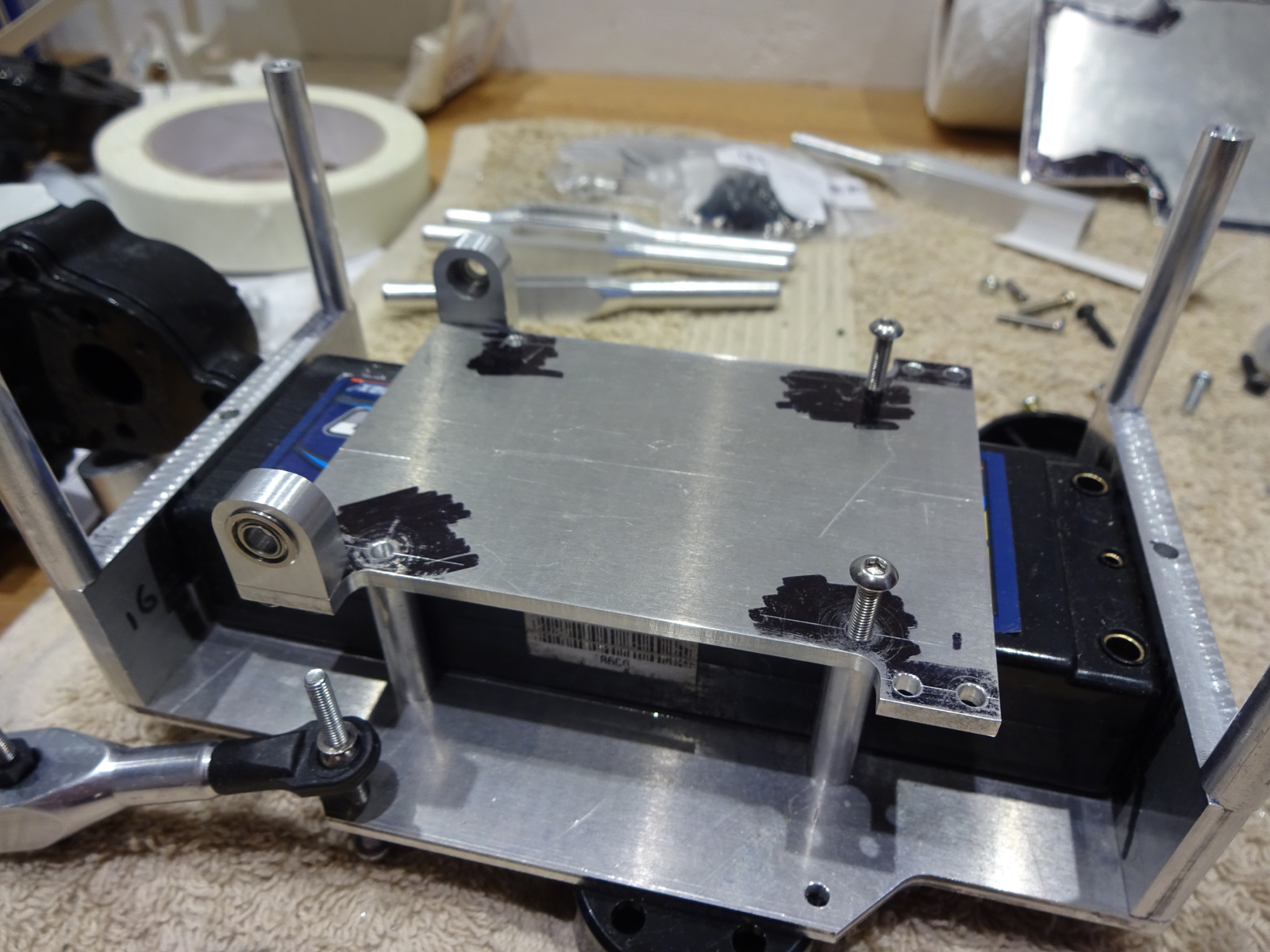

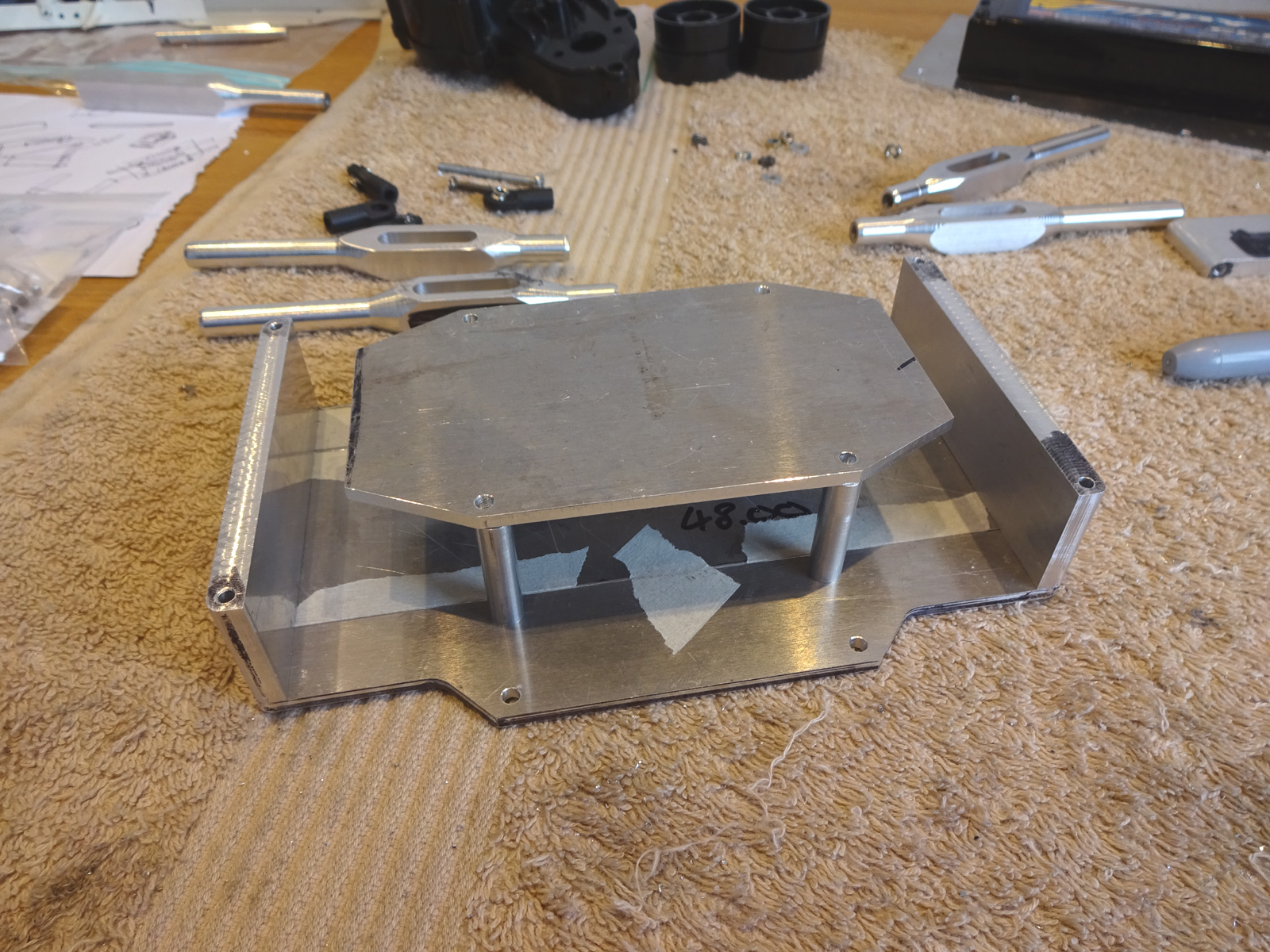

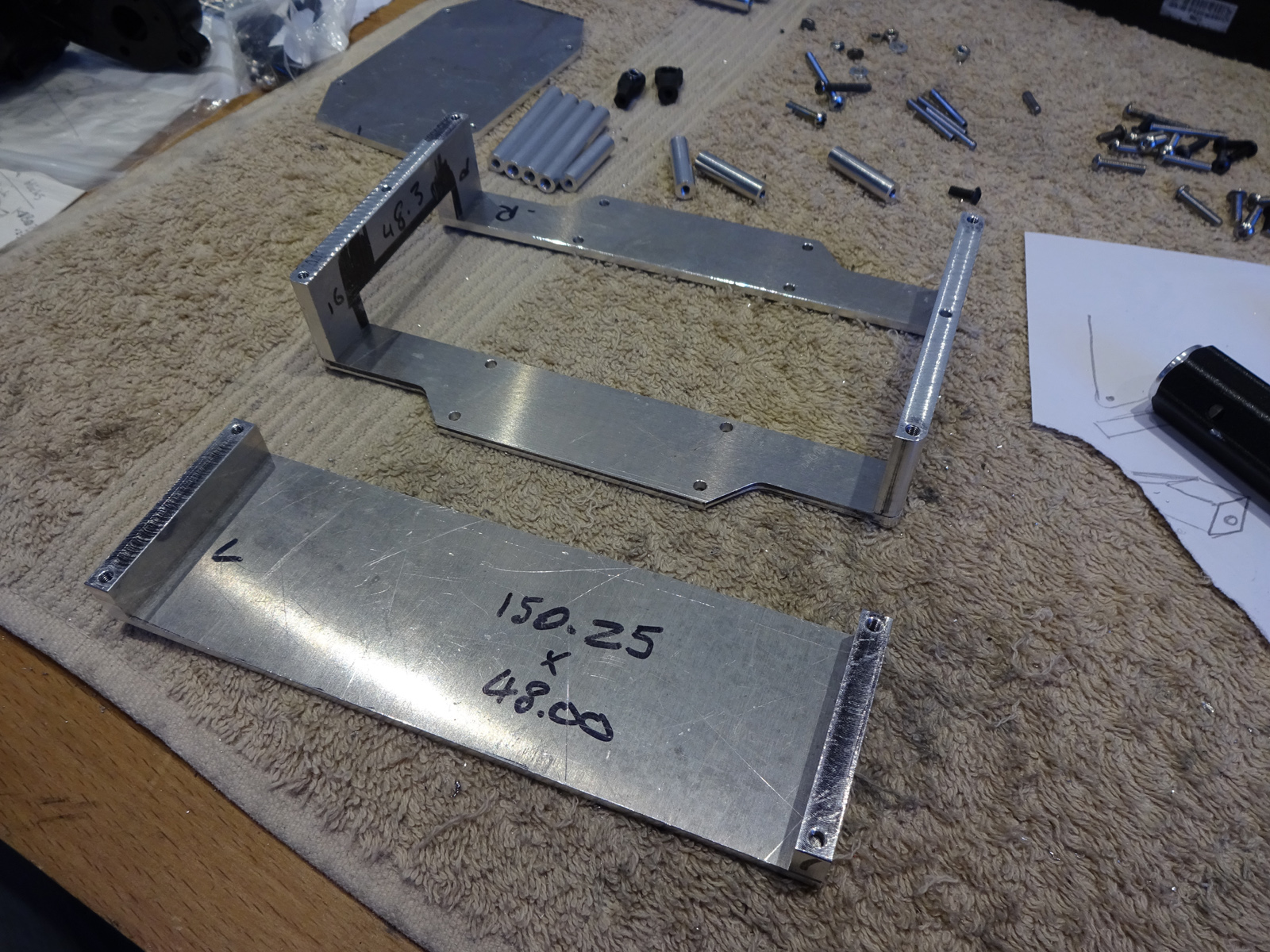

Back to the chassis, made another side and then the middle deck..... which may or may not be the right size.

Cut slots out of the sides and then new sections to attach to the battery tray.

so you can put the battery in the tray then load it from the bottom.

Some standoffs for the top deck, again, maybe

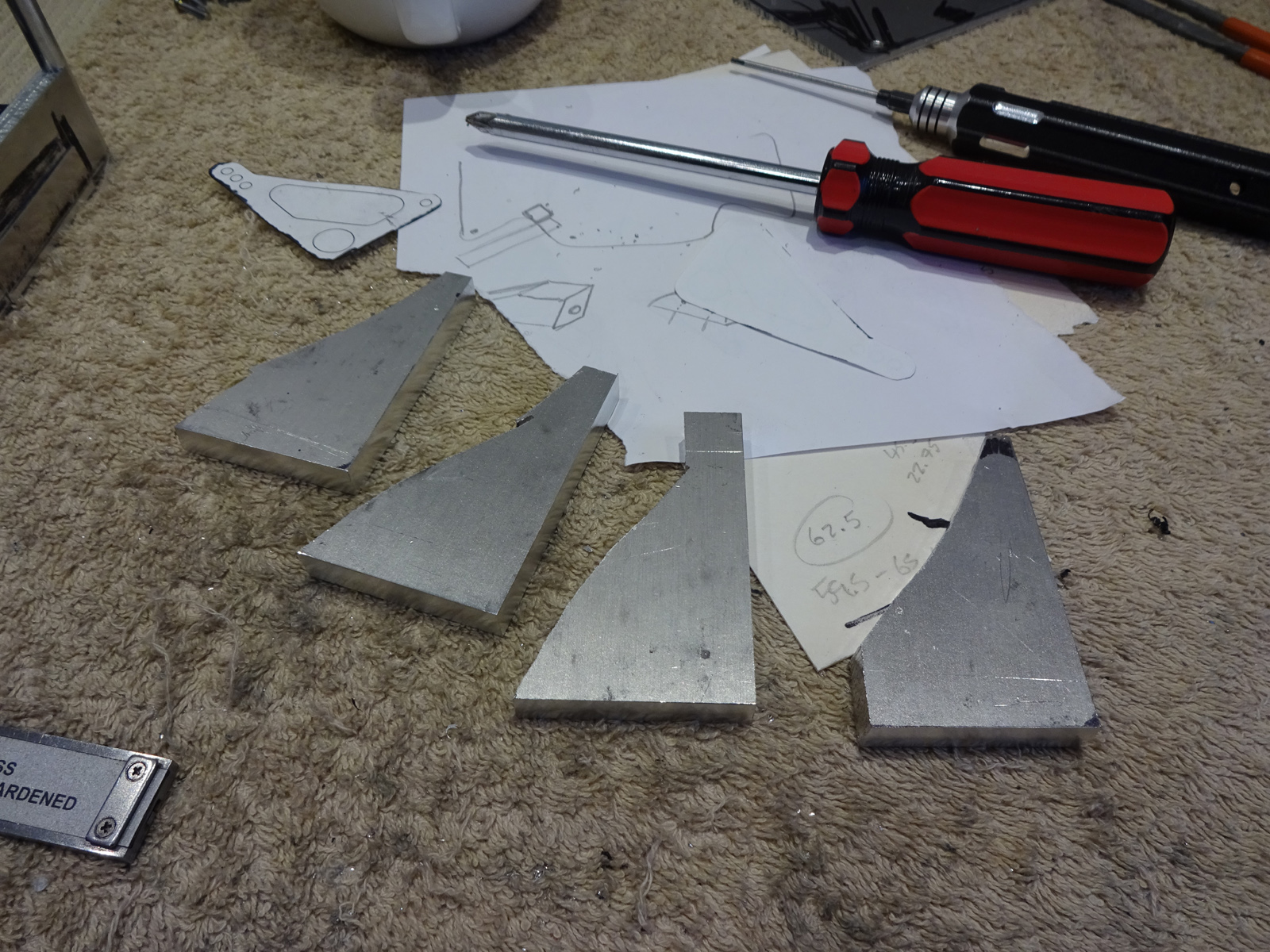

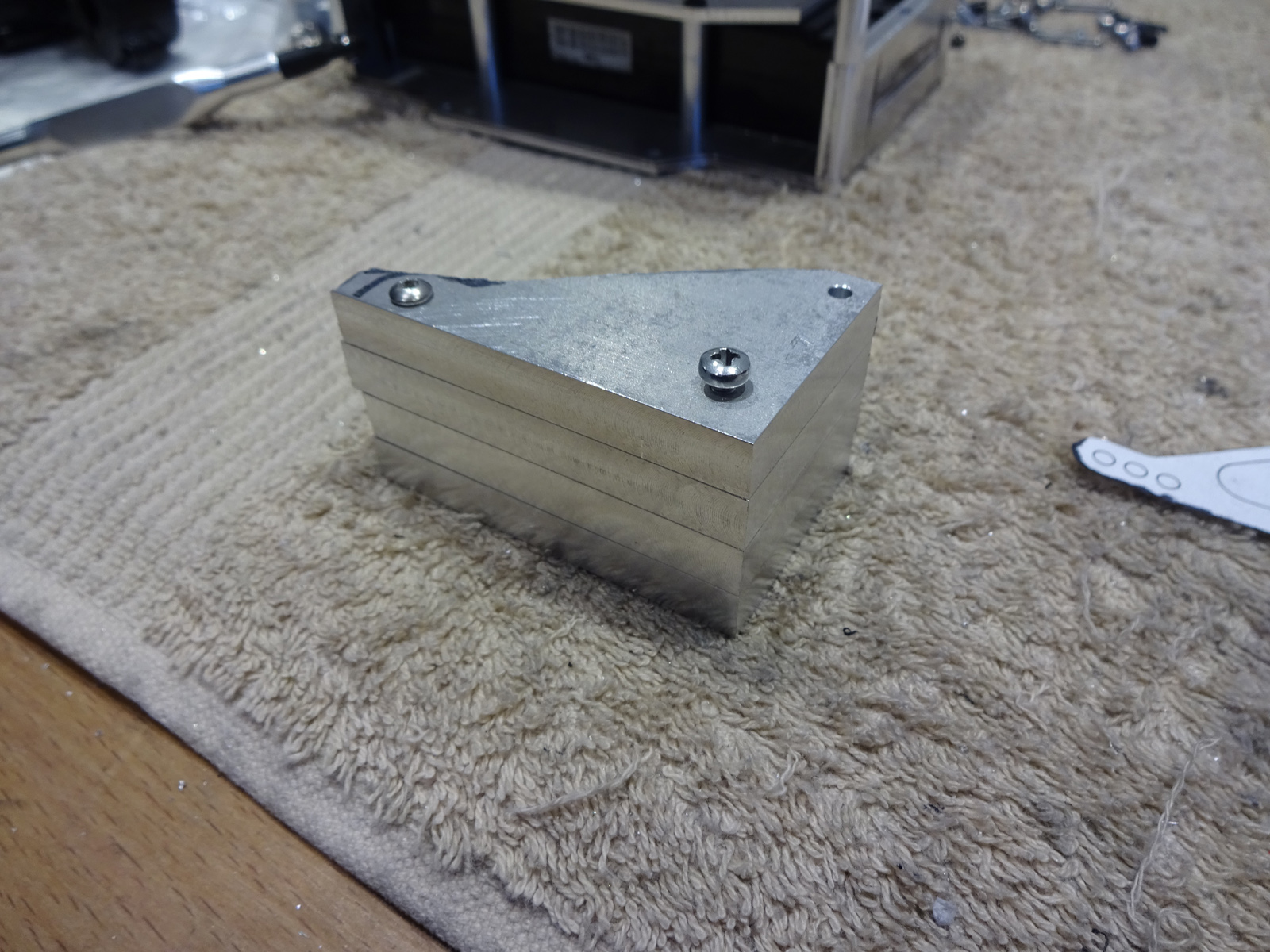

Ok, cantilever time! this should be fun, using 8mm thick, cut the rough shapes out with a hacksaw first.

Drilled one of them with the 3 holes where I wanted, then through them all in one corner in the same place and then bolted them together and drilled the holes through them all. With them all together like this its a lot easier to get them exactly the same and also much quicker.

Machining the flats on them and buzzing off the corners just to make the process of filing the radiuses a bit easier.

Trimmed all the corners ready for filing

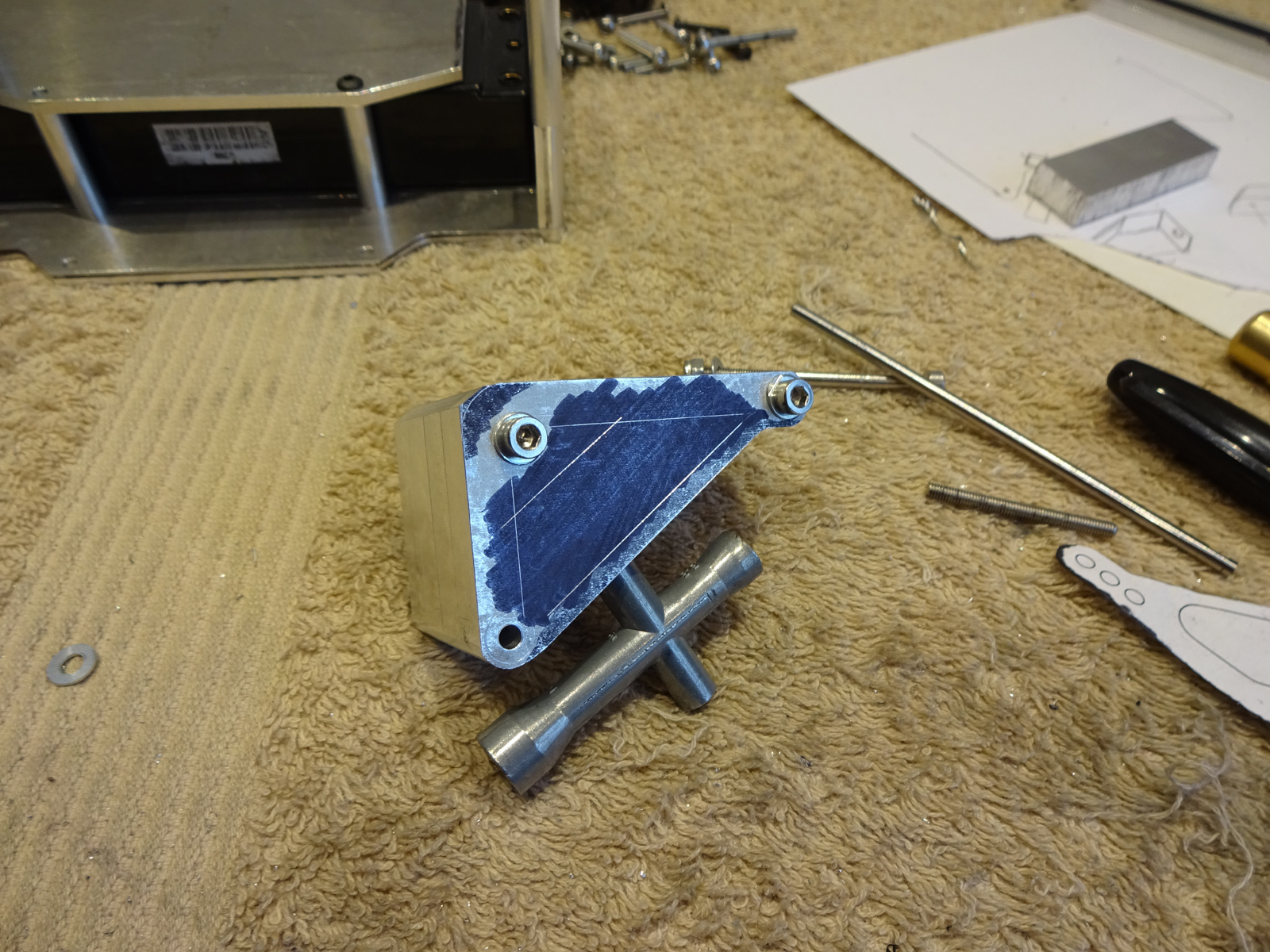

Split them into 2 lots of 2. They are 8mm thick, so machining the middle hole is ok for 16mm thick but trying to do all 4 at once would be a bit difficult. This poses its own problms, I have to cut up and down and then left and right making a note of where I start and how far I cut in each direction. Then I have to unclamp it and re-clamp on an angle to do the other 2 edges, again noting where I start and stop so when I do the other 2 I can do it exactly the same.

work in progress, clamped in position to do the up/down, left/right.

Drilled the hole for the bearings very carefully, then set it up in the mill and milled a 9.5mm hole. Next using my new tool, a reamer, no idea how I have got this far without owning any reamers before

I reamed the hole to a perfect 10mm so the bearing just presses in.

now its time to seperate them and give them a quick scrub wth some 1000 grit to see what we have.

really pleased with these, they look and feel proper.

Next up I wanted some sway bars running on bearings, this will be attached to the middle deck of the chassis.

I set the strip up in the mill then just worked my way down boring the holes and then did the last 0.2mm with the reamer to get a perfect 6mm for the flanged bearing to press into.

Cut them up and flattened the faces, then drilled 2 holes in the bottom of them all.

Curved the tops, mmmmm smoooth

Wasnt until I came to fit them I realised my middle deck was totally the wrong shape, So I had to make a new middle deck with some nice little wings for the mounts to sit on