|

||

|

|||||||||||||||

|

#1

|

||||

|

||||

|

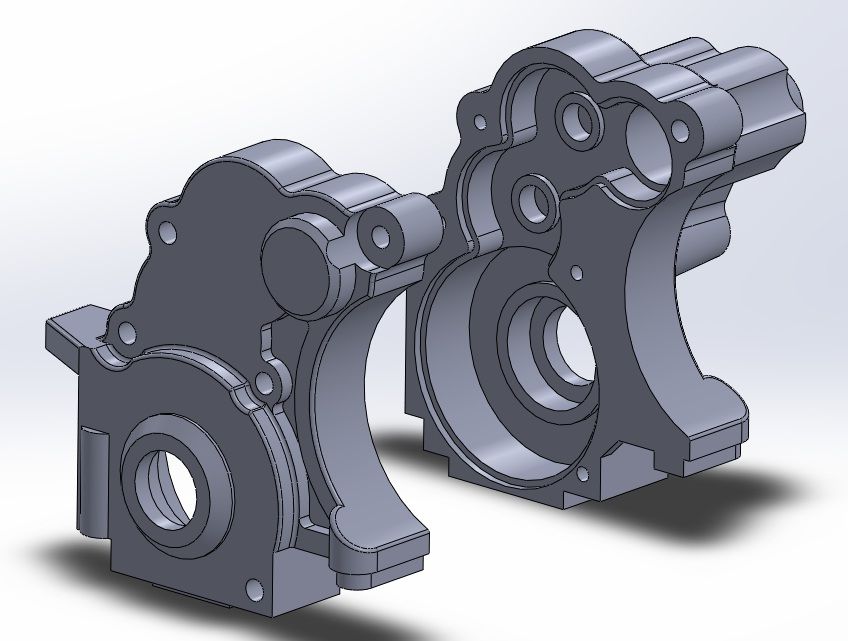

I've recently bought a second hand 22-despite people warning me about it being hard to set up in mid-motor configuration.

What I did notice was that the motor was a lot more forward than the norm, which might explain the aformentioned. So I figured it might be worth messing about a bit with the weight-distribution. Hence the idea to make a more compact gear-box as a means of achieving this, without having to resort to a radical redesign of the entire car. The design :  The motor is +/- 15mm more rearward; as an unfortunate side-effect, itís also +/-8mm higher, so my idea might actually have an adverse effect on handling. So far, Iíve got it 3d-printed, (printed with heated filament wire ) Helas the quality of the print is so poor it barely allows me to check my dimensions Ö.  Iíve requested prices to get a more decent print, but I think itís going to cost me an arm and a leg.. If anybodyís got any comments on the idea itself or how to get a decent quality print, Iíll be glad to listen Steven |

|

#2

|

||||

|

||||

|

I think you have the right idea. I fliped the rear arms around on mine to move the wheels forward to a normal length and more rear weight, but I think you're on to something a bit better. I don't think that having the motor a bit higher will have a big negative affect, I think moving it back will far out weigh the high CG

__________________

Andrew Burghgraef Great Hobbies selling rf dex210 pivot blocks, pm me for details |

|

#3

|

||||

|

||||

|

have you tried atomic carbon on here for 3d printing

__________________

MBModels - Schumacher Racing - Vapextech.co.uk - MRT - Savox - SMD |

|

#4

|

||||

|

||||

|

Not yet, it's "old-timer" isn't it - would he be willing to help for a fee ?

He himself is selling the tardis but it's worth a PM of course |

|

#5

|

||||

|

||||

|

I'm not sure I'd be keen on 8mm higher!

__________________

Nortech is ACE! |

|

#6

|

|||

|

|||

|

nows there is nice idea. surely with new motor plate or something, you could place the motor lower?

|

|

#7

|

||||

|

||||

|

Have you thought about having it CNC'd from Delrin at all ? Not sure if that might be cheaper, plus if you can get more people wanting one you could obviously do this on bulk = bringing unit cost down ?

Just throwing the idea in. PS - Bloomfield seems to make the mid-motor config work, and work well

__________________

If you have trader feedback for me please go to http://www.oople.com/forums/showthread.php?t=120160 - Thanks Currently utilising (abusing) Durango DEX210 / KO Propo Espritt III / Tekin / LRP / SpeedPassion / Savox |

|

#8

|

||||

|

||||

|

Sure, i've thought of having it CNC'ed but the CNC time does't come cheap - I now have a quote for around 86 pounds - printed in a mechanically resilient material ; if I should find a mechanist wiling to do it for about that price , I'd be happy

My driving skills aren't exactly at the Bloomfield- end of the spectrum lol |

|

#9

|

||||

|

||||

|

If you ask nice though he may share his setup for you

ouch £86 ! Worse thing is i think the delrin doesnt cost that much material wise...its probably only going to be about 5% of the cost i guess. Hope you do get what you want done though

__________________

If you have trader feedback for me please go to http://www.oople.com/forums/showthread.php?t=120160 - Thanks Currently utilising (abusing) Durango DEX210 / KO Propo Espritt III / Tekin / LRP / SpeedPassion / Savox |

|

#10

|

|||

|

|||

|

£86 sounds a bargin to me, I'd be very suprised if you get even remotely close to that for a one of machined gear box. Unless some one is doing it for spending money of course.

|

|

#11

|

||||

|

||||

|

Cool project!

3D printing will do very nicely, both in strength and accuracy. The FDM printed sample you have is not the neatest ever but does allow you to check if everything fits and 'works.' 3D printing will do very nicely, both in strength and accuracy. The FDM printed sample you have is not the neatest ever but does allow you to check if everything fits and 'works.'As you're messing around with gear meshes - plus a part that (even if it doesn't hold the shock tower or turnbuckle joints) is exposed to quite a few stresses, I would go for a stronger material - and an accurate one at that. CNC Machining is indeed quite expensive - and in fact, may be unnecessary: Option 1: Have the parts printed in a durable printing material (Nylon printed in an 'SLS' printer for example) - I predict that would set you back 30-40 euros and is just about as strong as nylon of the same blend when moulded  It is also very accurate. The only potential problem is that the material is slightly porous, so it might not repell all the dust and dirt. This though it easily solved by coating the thing on the outside with paint or glue. It is also very accurate. The only potential problem is that the material is slightly porous, so it might not repell all the dust and dirt. This though it easily solved by coating the thing on the outside with paint or glue.Option 2: Have the casings printed in an extremely detailed and smooth material - it will look moulded and smooth as silk! That's a good thing, because then you can make a silicon mould from these parts and cast (or vacuum mould) parts in these silicon moulds and resell them  It will be more expensive for a single set, but if you do 10 or 20 sets it's already money well spent. A downside to this is that any mods/customizations along the way will have to pay themselves back. It will be more expensive for a single set, but if you do 10 or 20 sets it's already money well spent. A downside to this is that any mods/customizations along the way will have to pay themselves back.I work at a small company nowadays that does research on polymers and 3D printing, so if you are looking for more information, help finding the right material(s) or even refer you to contacts in the printing business to get the parts made, don't hesitate to PM me  Edit: Am I seeing correctly that the front gearbox mounts are the limiting factor to lowering the motor any further? If so, perhaps it's an option to entirely skip these mountings, incorporate TLR4162 (the inboard motor guard) into the gearbox housing and use the chassis holes for that part as the front mounts? Or the holes beside the front suspension hanger of the rear suspension that are unused in the mid-motor setting?  It requires some re-thinking on the mountings of course, but if successful any concerns of adverse handling effects should be off the table It requires some re-thinking on the mountings of course, but if successful any concerns of adverse handling effects should be off the table

|

|

#12

|

|||

|

|||

|

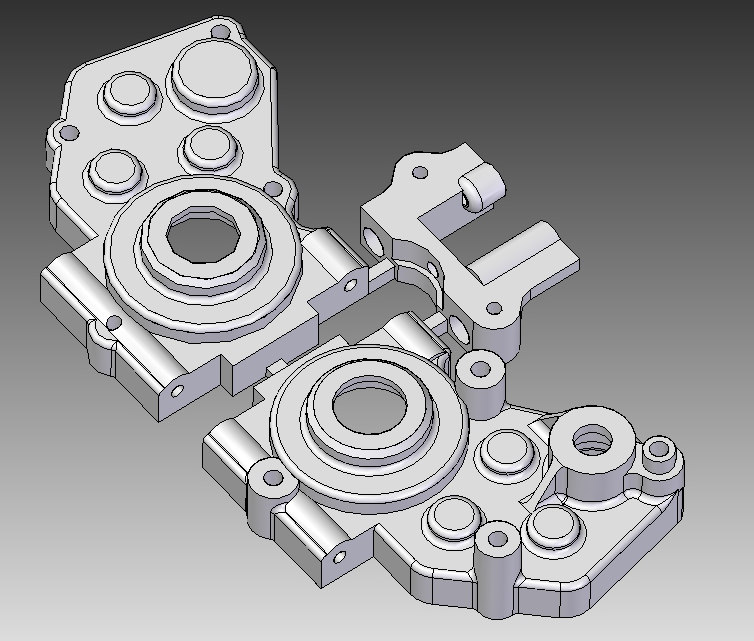

Hi,

you might want to check out shapeways.com . It's a company that does 3d printing (SLS) for "normal" people. They are based in the Netherlands. The prize for "strong + flexible plastic" (PA 2200) is $1,40 per cm≥ (white). I did a gearbox for my Academy GV2 mid-motor conversion, because I wanted an option to run 3 or 4 gears. Here is what my cad drawing and the final printout looked like:   My gear box has a total volume of about 20cm≥, shipping was $9,50 so you can do the math (~£25). I don't think you can get it cheaper than that. You might want to optimize material thickness on your model though to reduce costs. In addition to that, they have a handling fee for each part, so what I did for my three parts (the small one in the picture has nothing to do with the gear box) I connected them with a small link, so the whole assembly counts as one part. Accuracy was fine, even the gear mesh, holes and fittings tend to be on the smaller side, which I prefer anyways. Andi |

|

#13

|

||||

|

||||

|

Hi Andy,

Definitely worth looking into-a company in the Netherlands would suit me very well; I'm Belgian  Nice lokking design BTW. In the meantime I've had offers of help or valuable advice on the design from other forum-members (from, among others,Paul and Marc) all very much appreciated. For the moment I'm making small mods (read : a complete overhaul  ) on the design and we should be ready for printing. ) on the design and we should be ready for printing.Someone suggested some more mods for the front of the car I'll be lokking into after that. In the meantime I've run my other 22, build as a RM, for the first time indoor : against all expectations, it went really well  Grtz Steven |

|

#14

|

||||

|

||||

|

Great idea! This was always a problem with the 22, the motor was so far away from the driveshafts in mid configuration! Good to hear you're making this, bet it will make a huge difference in how the car drives. 8mm taller is NO problem in my opinion, after all you've got heavy big bore shocks on all corners, adding 8mm onto the central positioned gearbox won't make that much difference in comparison.

Good work

__________________

Schumacher ē Phat Bodies Mendip R/C Raceway - Offroad Racing in South-West WORM-Racing - GT12 Racing in the South-West

|

|

#15

|

||||

|

||||

|

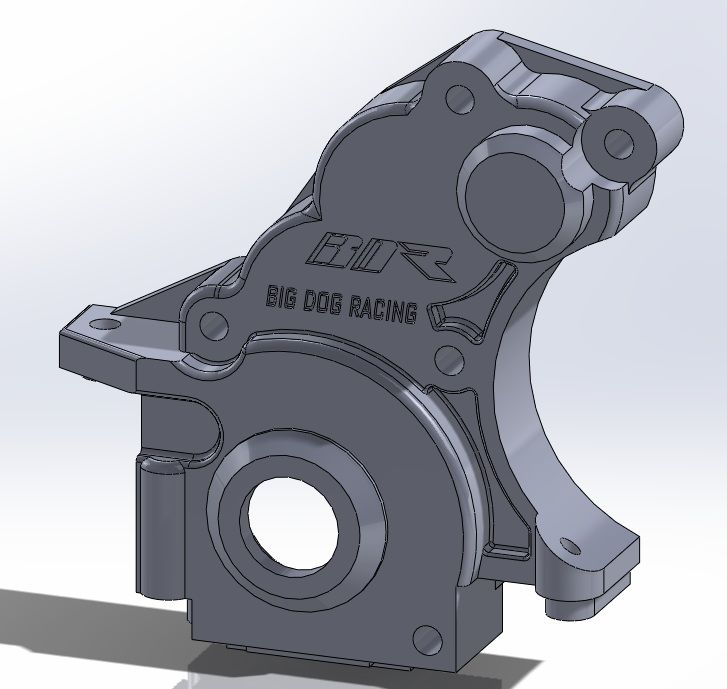

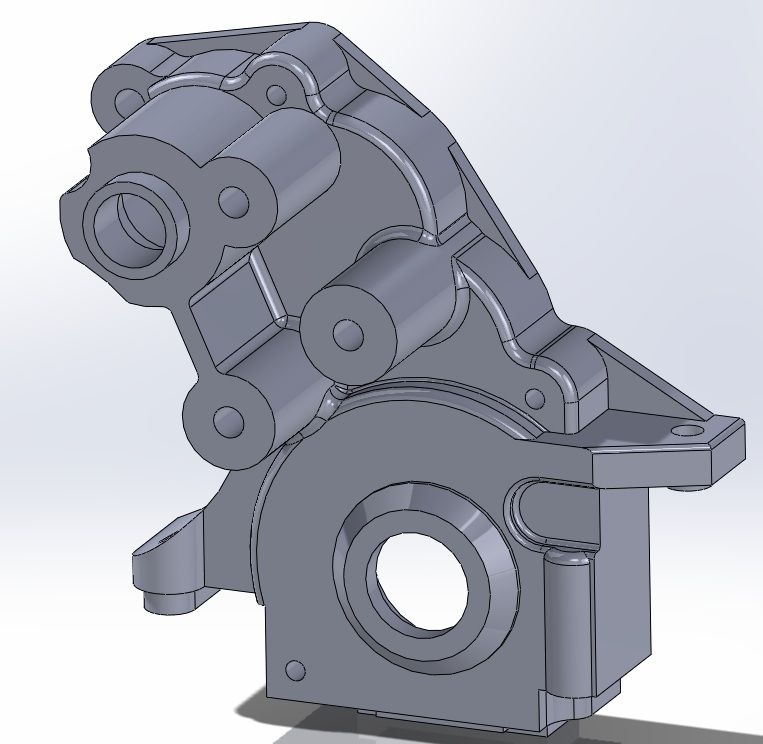

After some serious rework it should be ready for printing now:

Grtz Steven |

|

#16

|

|||

|

|||

|

Are you planning to sell these to fellow ooplers with 22's ? paypal waiting

__________________

Chris Hampson aka learnerdriver - lots of cars electric and nitro powered by visa

|

|

#17

|

||||

|

||||

|

Sure, if anyone should see the benefits of the design.

But first, I'd like to see if everything fits as it should. From what I've gathered so far, 3d printing in a useable material doesn't come cheap-even if I sold the part at cost (wich I'd more then willing to do) you'd be paying maybe tenfold of the original Losi part... In any case, I'll keep you posted Steven |

|

#18

|

|||

|

|||

|

Wouldn't it be more cost-effective to adapt the hobao H2 gearbox to your TLR22?

I do like your work though: hope to see it some time in real life. Where do you run? |

|

#19

|

||||

|

||||

|

Quote:

Lifting nearly 10% weight of a vehicle by 8mm won't cause any issues? really?

__________________

Mr F.Chimp |

|

#20

|

||||

|

||||

|

Maybe it would, but designing is half the fun.

I don't think you'd be willing to take the ferry to see it for real; I'm Belgian  Steven BTW : I'm pretty sure Mr. Chimp might have a valid point, this is just me tinkering and in no way intended as THE answer to potential set-up issues |

|

|

|